Description

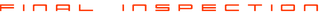

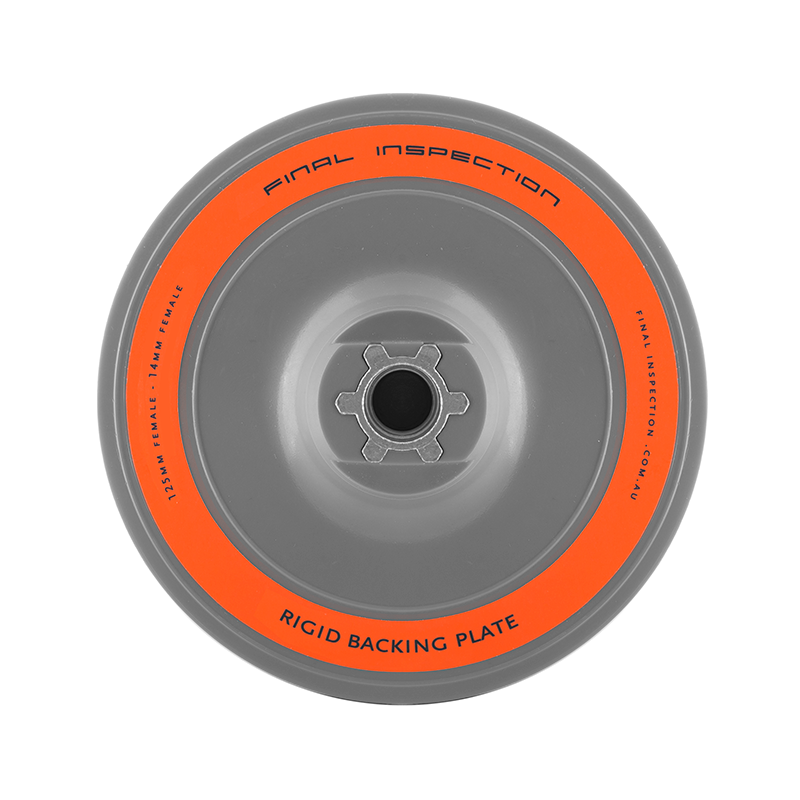

125mm Ø RIGID Backing Plate - to suit 135mm and 15omm Ø velcro-backed pads

To suit any female velcro backed 135 - 150mm polishing pad.

All Final Inspection backing plates feature Velcro® brand male velcro hook fastening material and are made from the highest construction quality to ensure safety, performance and durability.

This Rigid Backing Plate is very well priced, strong, simple and non-active so your movements, however subtle, are directly translated to action on the paint surface.

Final Inspection recommend the Active version of this for non-professionals or those new to polishing with a rotary machine.

Provides adequate (25mm) recess when mated to a 15omm (6") Ø pad and consistent and firm pressure all the way to the edge of a 135mm (5.3") Ø pad with enough recess for edge protection

Final Inspection backing plate sizes and pad suitability

- 75mm backing plates suitable for pads 90mm - 125mm diameter

- 125mm backing plates suitable for pads 135mm - 150mm diameter

- 175mm backing plates suitable for pads 200mm+ diameter

It is recommended to recess backing plates from pad edges by a minimum of 10mm and no more than 50mm, i.e. it is not recommended to use a 75mm backing plate with a 135mm pad as the diameter of the pad exceeds the diameter of the backing plate by more than 50mm making it difficult to properly centre and providing insufficient grip.

Rigid backing plates

Rigid backing plates are considered the professional option, they require a higher skill level and are less forgiving to incorrect technique by the operator.

Final Inspection rigid backing plates also have a significantly lower profile than an active backing plate which may assist polishing in cumbersome areas.

Final Inspection rigid backing plates weigh less, are cheaper and are slightly more durable than their active versions.

Active backing plate

Active backing plates are more forgiving in the sense that they will compensate for lift irregularities as a result of operator movements.

Active backing plates are recommended for polishing on curvy panels and for amateur operators who may tend to lift pads from the surface using only the edges of the pad, a tilted pad usually results in hologramming.

The active backing plate compensates by absorbing some of the pressure and maintaining a flat pad which dramatically reduces hologramming and increases polish efficiency.

NB: Backing plate does not come with pad (as shown in some images which is for illustrative purposes only).

Your backing plate may be Blue, Yellow, White or Red (depending on batch)